All types of pu-erh tea are created from "maocha", a mostly unoxidized green tea processed from a "large leaf" variety of Camellia sinensis found in the mountains of southern Yunnan. Maocha can undergo "ripening" for several months prior to being compressed to produce ripened pu-erh (also commonly known as "cooked pu-erh"), or be directly compressed to produce raw pu-erh.

While unaged and unprocessed raw pu-erh is technically a type of green tea, ripened or aged raw pu-erh has occasionally been mistakenly categorised as a subcategory of black tea due to the dark red colour of its leaves and liquor. However, pu-erh in both its ripened or aged forms has undergone secondary oxidization and fermentation caused both by organisms growing in the tea as well as from free-radical oxidation, thus making it a unique type of tea.

In China, where fully-oxidised tea ("black tea") is known as "red tea," pu-erh is indeed classified as a "black tea" (defined as post-fermented), something which is resented by some who argue for a separate category for pu-erh as most other black teas tend to be of low standard and status.

|

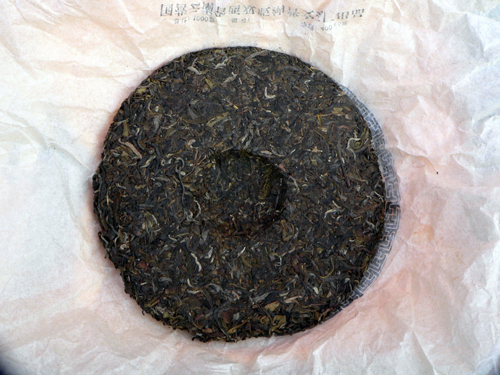

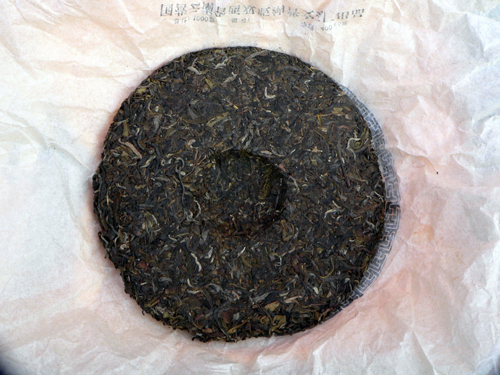

| A "Hand-pressed" pu-erh bing, revealing the hollow knot dimple in its rear face and an uneven edge |

To produce pu-erh many additional steps are needed prior to the actual pressing of the tea. First, a specific quantity of dry "maocha" or ripened tea leaves pertaining to the final weight of the bingcha is weighed out. The dry tea is then lightly steamed in perforated cans to soften and make it more tacky. This will allow it to hold together and not crumble during compression. A ticket, called a "Nei fei" or additional adornments, such as coloured ribbons, are placed on or in the midst of the leaves and inverted into a cloth bag or wrapped in cloth. The pouch of tea is gathered inside the cloth bag and wrung into a ball, with the extra cloth tied or coiled around itself. This coil or knot is what produces the dimpled indentation at the reverse side of a tea cake when pressed. Depending on the shape of pu-erh being produced, a cotton bag may or may not be used. For instance, brick or square teas often are not compressed using bags.

Depending on the desired product and speed, from quickest and tightest to slowest and loosest, pressing can either be done by:

Pressed pu-erh is removed from the cloth bag and placed on latticed shelves where they are allowed to air dry, which depending on the wetness of the pressed cakes may take several weeks or months. The pu-erh cakes are then individually wrapped by hand, and packaged in larger units for trade or commerce.